管家负责的水管理

我们使用基于风险的方法保护和保护水资源

Abdul Sule

Water Operations Supervisor

水声明

雪佛龙将水作为基本社会,环境和经济资源的价值认可。作为一家全球公司,我们知道对水资源的访问对于我们经营和业务的社区至关重要。为了在世界各地生产能源,我们依靠获得足够的水来源,包括淡水和较低质量的水。

We have management systems, processes and standards to manage this critical natural resource in alignment withThe Chevron Way和我们的人权政策。

To promote responsible management of water resources, we:

- 将水资源保护和效率司机整合到我们的决策过程中。

- 努力节省,重用和循环水受限区域中的水。

- Account for the use of water with appropriate metrics.

- 在我们运营的地区,与各国政府,合作伙伴,当地社区和其他利益攸关方聘用。

- 建立伙伴关系并参与行业水资源举措,以分享和促进最佳做法,协助发展行业标准和形状相关政策。

managing water use responsibly

Chevron strives to responsibly manage our water usage. For example, in the Permian Basin we have increased the reuse of water produced during oil operations. Chevron has implemented innovative produced water recycle strategies for drilling and completions that decreases reliance on other water sources. Research shows this reuse of produced water is not detrimental to well longevity because the chemistry of the underground formation undergoes fewer changes. Reuse of produced water for these operations is sensible and fit for purpose.

Likewise, our Canada business unit invested in freshwater storage and pipeline infrastructure in Kaybob Duvernay, Alberta, to reduce our operational footprint and reliance on river water during low-flow periods in summer and winter.

water management: management systems, processes and standards

The expectations in our updated Operational Excellence Management System (OEMS) call for our organizations to conserve and protect water resources using a risk-based approach that addresses potential acute and cumulative impacts across the life of our assets. Organizations monitor and analyze performance to verify that the safeguards designed to conserve and protect water in water-constrained areas are in place.

我们的环境管理程序,我们的环境,社会和健康影响评估(ESHIA)进程,以及我们的上游自然资源环境绩效标准(EPS)是如何执行对OEM与水有关的预期的三个例子。

ES流程指导我们的业务创建其活动如何与环境互动。然后,这些环境方面包括使用,以及它们的相关潜在影响,用于识别,评估和优先考虑环境风险和改进机会。

Eshia过程由项目的生命周期早期使用,以评估我们对包括水的自然资源的活动的潜在影响和益处。这一进程的一个重要部分正在评估现有的环境和社会条件,例如当地社区如何使用水。在项目规划期间使用此信息,以帮助我们考虑和解决我们与本地水资源可用性相关的潜在大量的用水。

Our Natural Resources EPS is applied across our onshore Upstream business and capital projects and calls for a water resources screening assessment. Together with our ESHIA process, these tools help to identify potentially significant environmental and social impacts associated with our water use. The water resources screening assessment evaluates and helps us manage the following risks that may be associated with our water use:

- 水可用性

- Competition for water resources

- 戒烟对源水质或数量的影响

- Sociopolitical risks

- Regulatory restrictions

Where there is potential for significant impacts, a water resources management plan (WRMP) is developed. The WRMP helps our operations identify and implement measures that reduce water withdrawals when possible.

reporting our performance

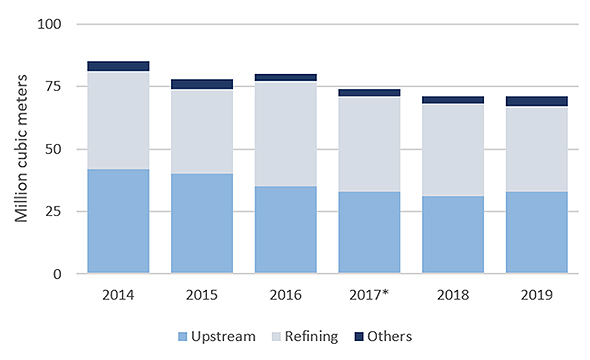

我们收集有关我们退出环境的新鲜和非新鲜水量的数据,恢复到淡水来源的淡水量,使我们能够在水管理周围做出明智的业务决策。此外,我们每年报告2015 IPIECA / API / IOGP中指定的公共报告元素的性能数据石油和天然气行业关于自愿可持续发展报告的指导bob体彩靠谱吗。

fresh water withdrawn

success stories

管理液压压裂中的用水

Chevron strives to minimize the amount of fresh water used in our hydraulic fracturing operations.

Using alternate sources of water in the Permian

在二叠纪盆地,我们主要使用咸水和再生产水代替淡水。今天,我们井井完井中使用的99%以上的水是来自咸水或再生水源。

在我们的炼油厂回收水资源

裕廊岛,新加坡

2017年,新加坡国家水务机构授予the Singapore Refining Company (SRC)* the inaugural Water Efficiency Award in the Refining category for its efforts in water recycling. The SRC built a recycling plant that further manages treated wastewater that would otherwise be discharged to the sea. The plant uses ceramic microfiltration and reverse osmosis, removing suspended solids, oil, grease and other contaminants from the used water. Water from the new plant meets both industrial and potable water specifications and is recycled back to the refinery’s boiler feed water. The plant currently meets approximately 20 percent of the SRC’s water demand.

里士满,加利福尼亚州

We have invested in technologies to reduce our freshwater usage. As a result, our refinery in Richmond, California, has become the largest industrial user of reclaimed water in the San Francisco Bay Area. Together with our partners, we have worked to overcome barriers to reclaimed water use. One such project that contributed to this achievement was the Richmond Advanced Recycled Expansion (RARE), a joint effort with the East Bay Municipal Water District. Through innovation and collaboration, the RARE Water Project facility greatly increased the daily allowable capacity for use of reclaimed water at the refinery, to more than 6 million gallons.

El Segundo, California

At our El Segundo, California, refinery, approximately 70 percent of the water used in refinery processes and landscaping is recycled or reclaimed water. The El Segundo refinery is the largest industrial user of reclaimed water in the Los Angeles Basin. Using reclaimed water helps our environment by significantly reducing the treated wastewater discharged to the Santa Monica Bay.

*较低质量的水可包括:海水,咸水地下水或地表水,来自另一个市政或工业设施,淡淡的水的回收废水;用于工业用途的修复地下水。

**在提取油气时带到表面的水

*** A Chevron 50 percent-owned joint venture.